What Is Camp Brisket?

Camp Brisket is an annual two-day class focusing on the art and science of cooking your best brisket. The agenda includes brisket anatomy, quality grading, brisket trimming, seasoning, cooking, resting, slicing, and comparative tastings. It’s a collaboration between Foodways Texas, an organization that preserves and promotes Texas food culture, and the Meat Science program of the Department of Animal Science at Texas A&M University (TAMU).

The 2020 camp was held January 10-11 at the Rosenthal Meat Center on the Texas A&M campus and at the nearby Beef Cattle Center at the O.D. Butler Animal Science Complex.

2020 marked the eighth year for Camp Brisket, and it’s not an easy event to get into. First, you have to be a member of Foodways Texas at a cost of $75/year for an individual membership. Second, you have to submit your name to a random drawing. If selected, the $495 registration fee covers:

- Seven instructional sessions and three panel discussions.

- A comparative taste test brisket lunch on Days 1 and 2.

- A full brisket dinner with sides and dessert on Day 1.

- A chuckwagon-style breakfast on Day 2.

- A comparative taste test brisket dinner on Day 2.

About 70 barbecue pitmasters and backyard fanatics attended Camp Brisket 2020. Some of these people had waited patiently for many years to get into the camp. The drawing process is weighted based on your length of Foodways Texas membership and whether you’ve attended Camp Brisket in the past. The longer you’ve been waiting, the more likely you’ll be chosen in the drawing.

Camp Brisket 2020 Photo Album

See all 195 photos I took at Camp Brisket 2020 in this Facebook photo album.

Day 1: Introductions All Around

Camp Brisket Day 1 began at 8:00AM on Friday. Martin Bendele of Foodways Texas and Dr. Jeff Savell of the TAMU Meat Science program welcomed us and kicked things off with introductions. We went around the large amphitheater-style classroom introducing ourselves row by row. It took more than the one hour allocated on the agenda to get through everyone, but it was interesting to hear where people came from, to learn about their diverse backgrounds, and to hear what they wanted to get out of the class. It helped build a sense of connection and community as we launched into this two-day deep-dive into brisket.

When I introduced myself, I mentioned that I published this website and asked how many people had experience using a Weber smoker, either now or in their barbecue past. Almost half the hands in the room shot up! Boy, was I surprised! I had a chance to meet and greet many of these folks over the course of the next two days, many expressing thanks for the website and telling me how it got them started on the right track.

Perhaps most gratifying was talking with Danielle Bennett. You know her as barbecue pitmaster and media personality Diva Q. She recounted how her early barbecue days in 2006-2007 included frequent visits to The Virtual Weber Bulletin Board where she asked lots of beginner questions and got helpful answers from forum members. That made me feel really good!

We had people in attendance from as far away as Australia and South Korea. We had husbands and wives, fathers and sons, even a mother and son. We had barbecue professionals and backyard enthusiasts. We had a lot of frustrated IT professionals and lawyers in the class, which turns out to be a common occurrence each year.

We were honored to spend time with some heavy hitters in the barbecue community over the two days:

- Owner Kerry Bexley and legendary pitmaster Tootsie Tomanetz of Snow’s BBQ in Lexington, TX, the #1 barbecue joint in all of Texas according to Texas Monthly magazine in 2017.

- Todd David: Owner of Cattleack Barbeque in Dallas, the #3 barbecue joint in all of Texas according to Texas Monthly magazine in 2017.

- Wayne Mueller: Owner of Louie Mueller Barbecue in Taylor, TX, the #5 barbecue joint in all of Texas according to Texas Monthly magazine in 2017.

- Arnis Robbins: Owner of Evie Mae’s Pit Barbecue in Wolfforth, TX, the #9 barbecue joint in all of Texas according to Texas Monthly magazine in 2017.

- Russell Roegels: Owner of Roegels Barbecue Co. in Houston, a Top 50 barbecue joint in all of Texas according to Texas Monthly magazine in 2017.

- Bryan Bracewell: Owner of Southside Market & Barbecue in Elgin, Bastrop, and Austin, TX.

- John Brotherton: Owner of Brotherton’s Black Iron Barbecue in Pfluegerville, TX; pitmasters Dominic Colbert and Alanmykal Jackson.

- Danielle Bennett aka Diva Q: Competition barbecue pitmaster, instructor, media personality, Traeger brand ambassador, and author of Diva Q’s Barbecue.

- Jess Pryles: Chef, blogger, media personality, and author of Hardcore Carnivore.

- Daniel Vaughn: BBQ Editor at Texas Monthly magazine and author of The Prophets of Smoked Meat: A Journey Through Texas Barbecue.

- Kevin Kolman, Head Grill Master, and Dustin Green, Culinary Grill Master, Weber-Stephen Products LLC.

- Ryan Zboril: CEO & Owner of Pitts & Spitts Smokers & Grills.

- Sunny Moberg: Owner of Moberg Smokers.

- Ryan Heger: Senior food scientist at Adams Extract & Spice.

- Dr. Nick Nickelson: Food safety consultant and co-owner of The Meat Board restaurant/butcher shop in Fort Worth.

- Homer Robertson: World champion chuck wagon cook-off winner and Assistant Chief, Fort Worth Fire Dept.

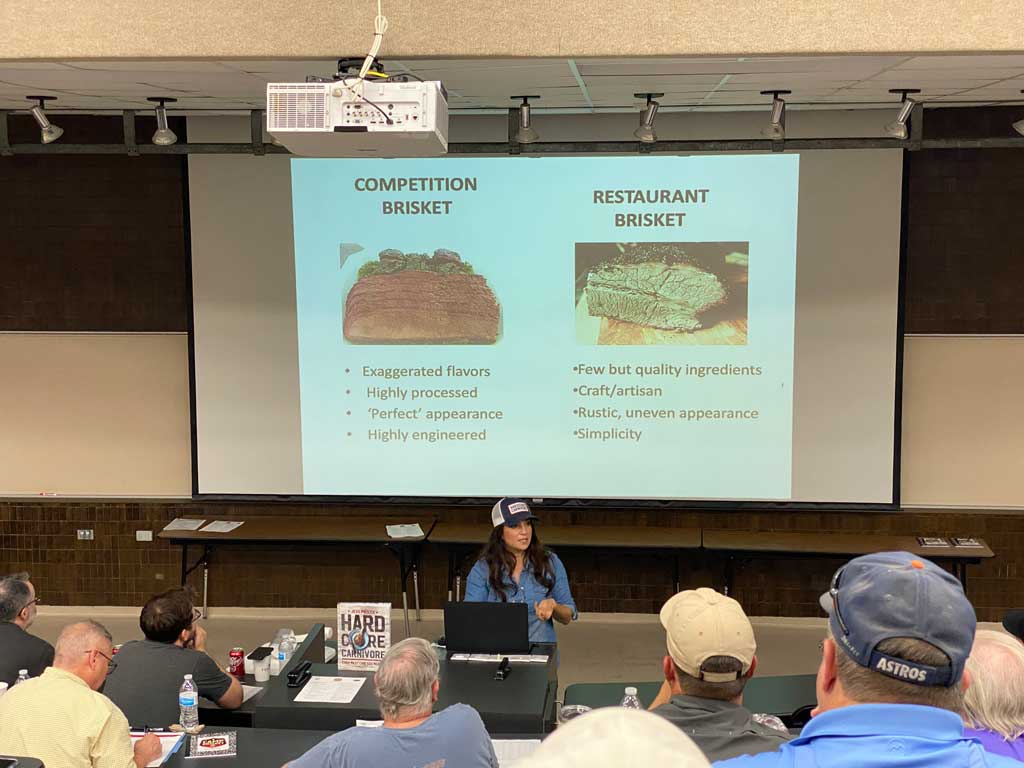

Comparing Restaurant & Competition Style Brisket

The first talk of Day 1 was by Jess Pryles, a chef, blogger, media personality, and author of Hardcore Carnivore. Comparing restaurant vs. competition style brisket seemed like an odd choice for the first topic of the class, but I think it was due to Jess’s schedule as she left during the morning break and didn’t return.

The attributes that characterize competition brisket include:

- Exaggerated flavors

- Highly processed

- “Perfect” appearance

- Highly engineered

The attributes that characterize restaurant brisket include:

- Few but quality ingredients

- Craft/artisan

- Rustic, uneven appearance

- Simplicity

When it comes to competition brisket, we’re talking about brisket that’s cooked to win, not brisket that’s the best to eat. Judges may take only one or two bites of each entry and render a score, so the competitor needs to deliver the perfect, tender, moist and flavor-packed brisket. To achieve this, competitors select big, expensive USDA Prime or American Wagyu briskets, trim them to perfection, inject them with all sorts of ingredients, rub them with multiple spice rubs, spritz them during cooking, wrap them in aluminum foil toward the end of the cooking process, and brush the slices and burnt ends with a thin liquid or sauce so that everything looks moist and delicious when presented to the judges.

With restaurant brisket, things are simpler. The top restaurants use USDA Prime briskets, but there are exceptions. At the time of writing, the #1 rated barbecue joint in Texas, Snow’s BBQ, uses USDA Select and Choice brisket weighing just 7-8 pounds and wraps them in aluminum foil two-thirds of the way through the cooking process to keep in the moisture. In Central Texas, the only preparation is trimming the brisket to remove excess fat and improve its shape, then the application of rub, often a simple “Dalmatian Rub” of kosher salt and black pepper, smoking over post oak, finishing in butcher paper and resting for several hours before serving to customers.

Ms. Pryles also talked about burnt ends—what they were historically and methods used to produce them today, including non-beef examples like pork belly burnt ends.

Toward the end of her presentation, Ms. Pryles put up two spreadsheets showing survey results for some top competition barbecue teams and top barbecue restaurants, including:

- Type/brand/grade of brisket used

- Whether grain or grass fed

- Finished internal temperature

- Preferred weight of brisket used

- Whether injected

- Whether wrapped and with what material

- Trimming method

- Salt & pepper rub only or something else

It was interesting to see the similarities and differences between the two groups:

- All competitors were using Wagyu or USDA Prime briskets; restaurants were using USDA Prime, branded beef upper USDA Choice (e.g. Chairman’s Reserve, Certified Angus Beef), USDA Choice, or a combination of these.

- Everyone’s using grain-fed beef.

- 202-205°F is a common finished internal temp for teams with a range of 194-211°F; for restaurants it’s 200-205°F with a range of 184-208°F.

- Many in both camps say “feel” is part of determining doneness.

- Competitors like big briskets, 16-20 pounds is common; restaurants use smaller brisket, 12-14 pounds is common and 17 pounds was the largest.

- All competition teams injected their briskets; none of the restaurants use injection.

- All teams wrapped with aluminum foil; almost all restaurants wrapped with butcher paper.

- Almost everyone in both camps trim their briskets to 1/4″ fat.

- None of the competition teams use only a salt & pepper rub; about 2/3 of the restaurants use only S&P.

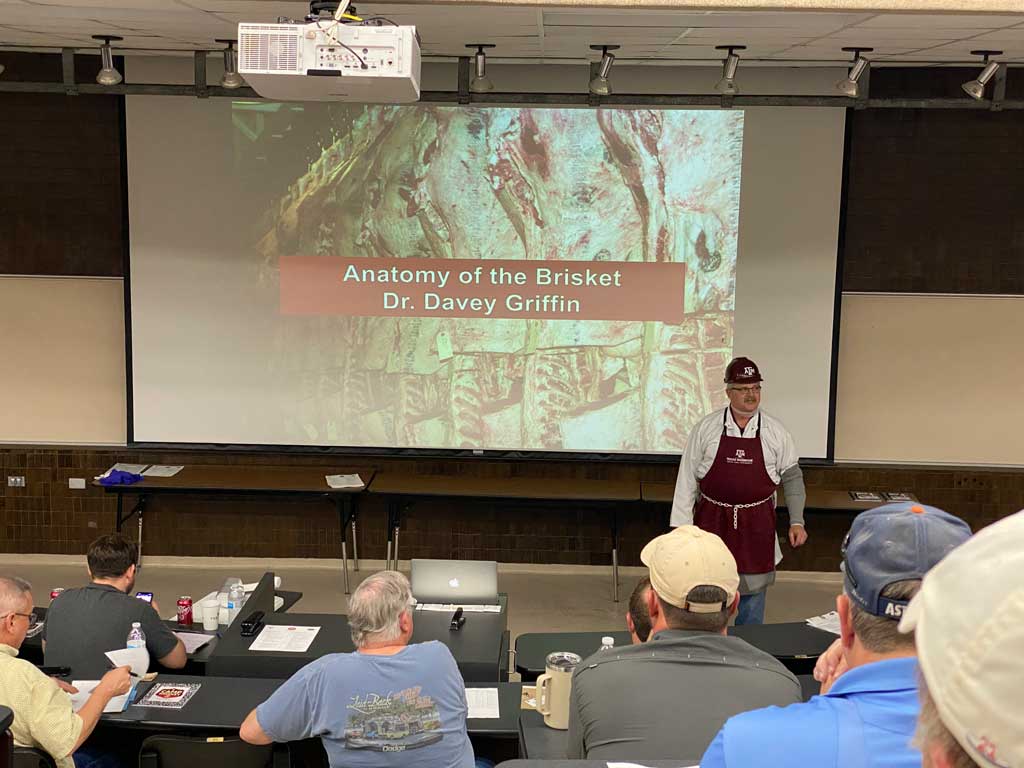

Anatomy Of A Brisket

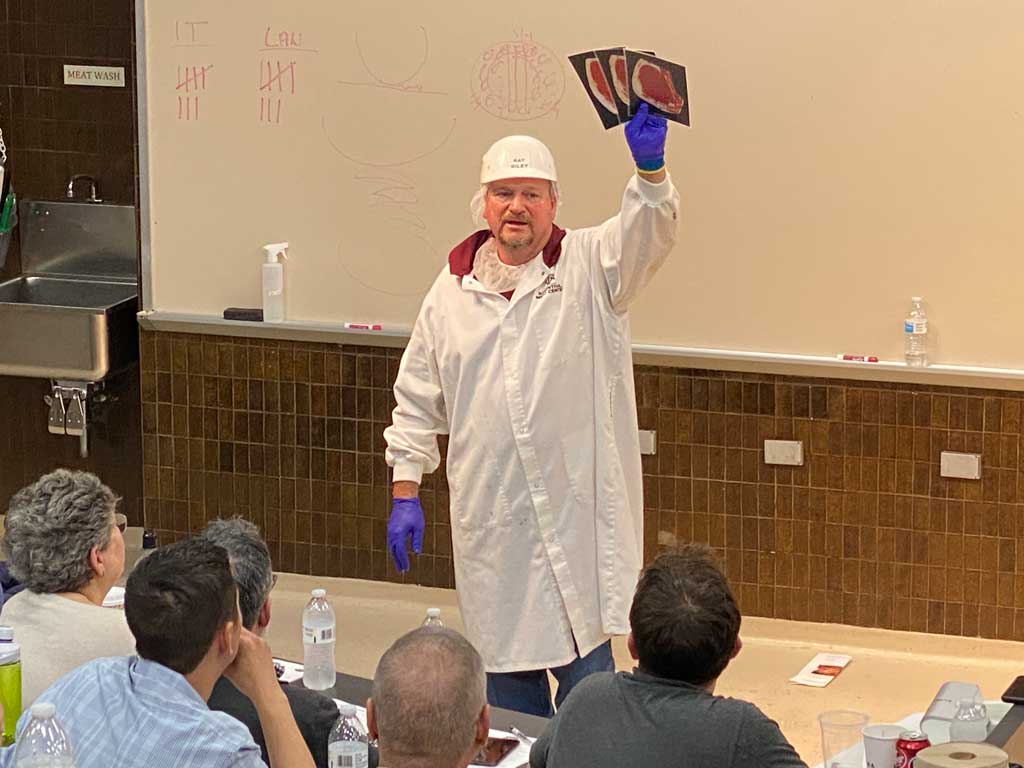

This section of the class was taught by Dr. Davey Griffin, a professor, Extension Meat Specialist, and a member of the Meat Science section in the Department of Animal Science. It was a wide-ranging discussion that covered a lot of topics about brisket.

Dr. Griffin entered the classroom dressed in a white meat cutters uniform, complete with TAMU apron and hard hat, and started the lecture. Shortly thereafter, an assistant rolled a side of beef into the classroom using an overhead track system. Wow, talk about a showstopping moment!

Taking a packer brisket in hand, Dr. Griffin placed it on top of the chest area of the carcass to show students where the brisket lives. He then showed a video in which a bone-in brisket is cut from the carcass, then the bones are removed to render the whole brisket we know. An initial cut is made between the 5th and 6th ribs to separate the chuck subprimal from the rib subprimal. Starting at the end of the 1st rib, a cut is made at 90° to the initial cut and all the way back to meet the initial cut between the 5th and 6th ribs. This is indicated in the lower right portion of the diagram below.

Dr. Griffin said that cattle spend 180-200 days at feed lots prior to slaughter. They come in weighing 700-800 pounds and leave weighing 1,300-1,500 pounds. On average, cattle are slaughtered at 14-24 months of age.

At the slaughterhouse, cattle are stunned, suspended by a hind leg, bled out, hide removed, head and shanks removed, eviscerated, cut into halves, rinsed to remove contaminants, and refrigerated for 36-48 hours before quality grading.

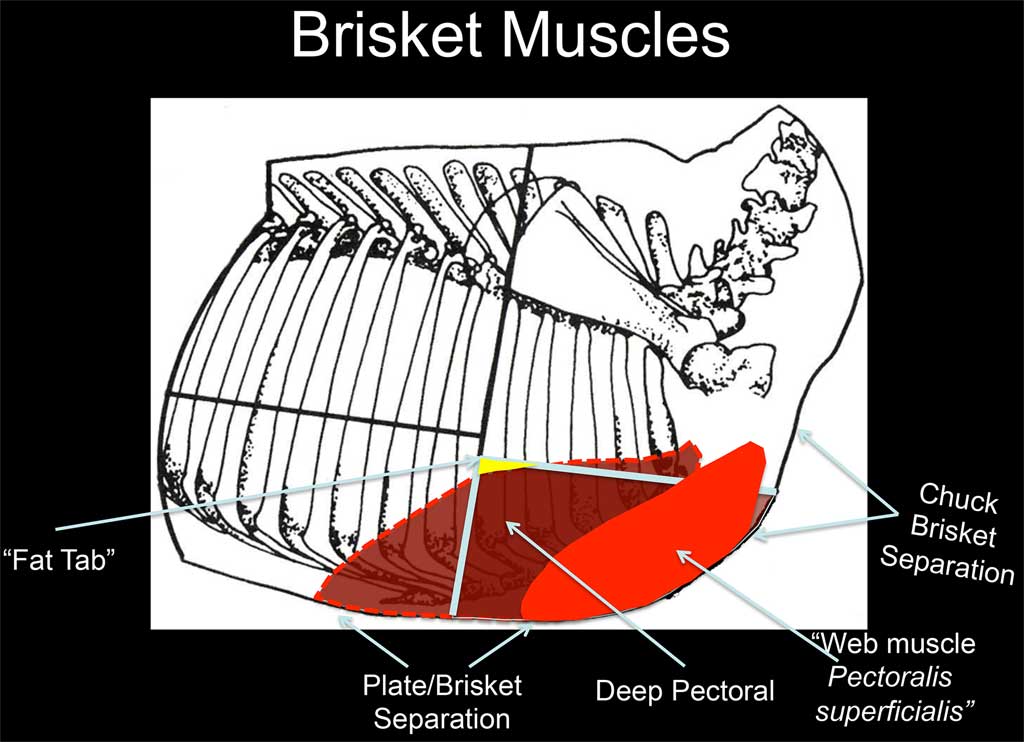

Brisket Terminology

The inside portion of the brisket is the flat. It is known as the deep pectoral muscle or pectoralis profundi. The outside portion of the brisket is the point. It is known the superficial pectoral muscle or pectoralis superficialis.

The deckle is the hard connective fat between the bones and the lean side of the brisket flat. Brisket point is sometimes mistakenly referred to as the deckle. The deckle is never included in briskets we buy here in the United States.

The Changing Shape Of Brisket: Longer, Narrower, Thin Flats

Briskets are cut longer and narrower today than in years past. Beef processors figured out that the edge of the brisket could be sold more profitably when left attached to other more expensive cuts of meat, so briskets got narrower. To make up for the loss, briskets are now cut longer, more likely between the 5th and 6th ribs instead of between the 4th and 5th ribs. This results in the thin flats commonly seen on briskets today.

Why Is The Edge Of My Brisket Gray?

The gray edge found on briskets is the result of the rinsing process during slaughter. Carcasses are rinsed with warm water, sometimes including lactic acid or acetic acid. This “cooks” the exposed edge of the brisket, resulting in the gray color. While safe to eat, you may wish to trim off the gray edge before barbecuing the brisket.

Hard & Soft Beef Fat

Differences between hard and soft beef fat are related to its content (soft fat contains more oleic acid) and its usage (soft connective fat between muscles moves, hard subcutaneous fat does not move).

Safety Grading Vs. Quality Grading

All beef in the United States is inspected for safety. Beef cannot go into commerce without safety inspection. However, quality grading is voluntary and optional. It’s administered by the USDA and paid for by the beef packer.

Freezing Briskets

Beef freezes between 28-32°F. The faster you can freeze beef, the smaller the size of ice crystals that form within the beef. Big ice crystals rupture cell walls, small ice crystals not so much. Smaller ice crystals result in less cell damage and less purge (liquid) coming out of the meat when thawed.

There was some discussion on Day 2 about using sous vide to reheat frozen brisket with great success.

Does Wet Aging Improve Brisket?

Briskets don’t necessarily benefit from wet aging the way rib and strip steaks do. A TAMU study in which briskets were wet aged up to 35 days showed that when prepared using a Texas-style barbecue method, wet aging did not improve the tenderness, juiciness, flavor, and overall liking of the brisket.

Some people are interested in knowing the pack date shown on the end of the brisket case box, especially when wet aging briskets. The pack date is the date the brisket was sealing in the Cryovac packaging. You should assume that the brisket was fabricated about two days before the pack date. It takes about 14 days for a brisket to go from slaughter to the supermarket meat case.

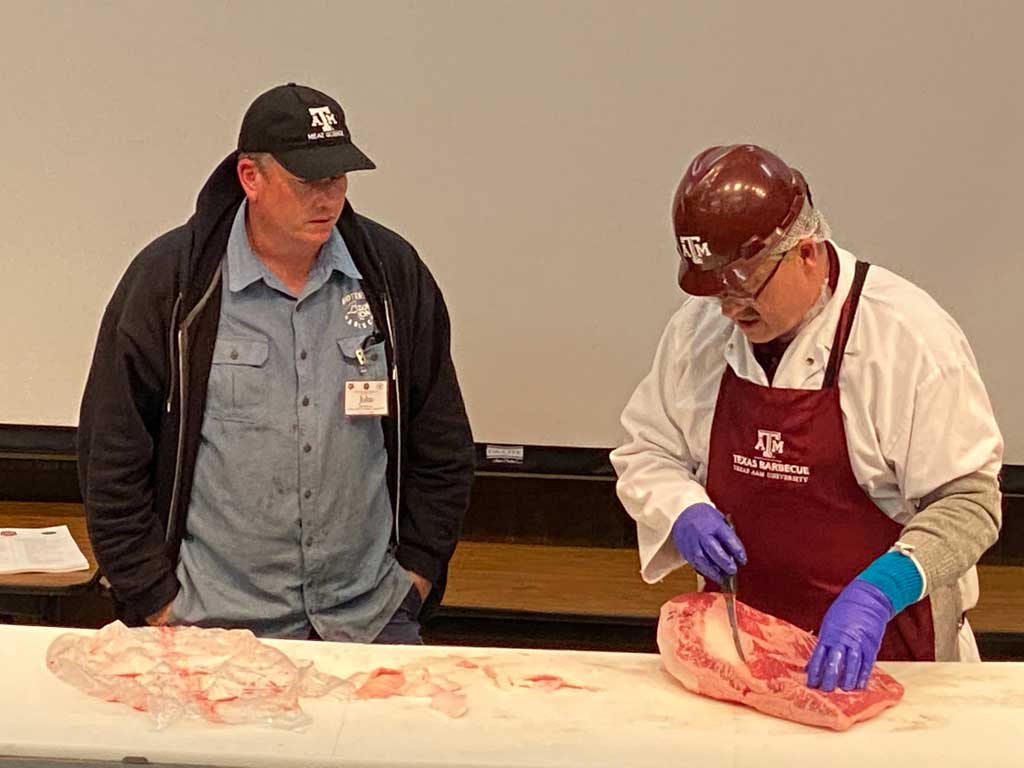

Brisket Trimming

A packer brisket was unwrapped and trimmed by Dr. Davey Griffin under the watchful eye of John Brotherton, owner of Brotherton’s Black Iron Barbecue in Pfluegerville, TX. The fat cap was trimmed to 1/4″ thickness. The hard fat seam between point and flat was trimmed flush to the brisket, not dug out. The gray edge of the brisket was trimmed off. The thin edge of the flat was removed. Thin areas of fat and silverskin were not removed from the flat.

The brisket was given an overall “aerodynamic” shape as popularized by Aaron Franklin. You can watch Aaron Franklin trim a brisket in this video from Camp Brisket 2015.

Mr. Brotherton suggested buying pre-trimmed briskets if you’re in the restaurant business. His pitmasters spend only 2-3 minutes per brisket on trimming. In Texas, you can buy pre-trimmed whole briskets in the supermarket; I don’t have access to brisket like that where I live, and you probably don’t, either.

You can mark a brisket to assist in slicing across the grain after cooking, just make a small perpendicular cut across the grain of the flat. Mr. Brotherton said that in his restaurant, they’re not too particular about slicing brisket exactly across the grain…it just doesn’t matter that much to the end product.

Close-up of a marked brisket (not a Camp Brisket photo)

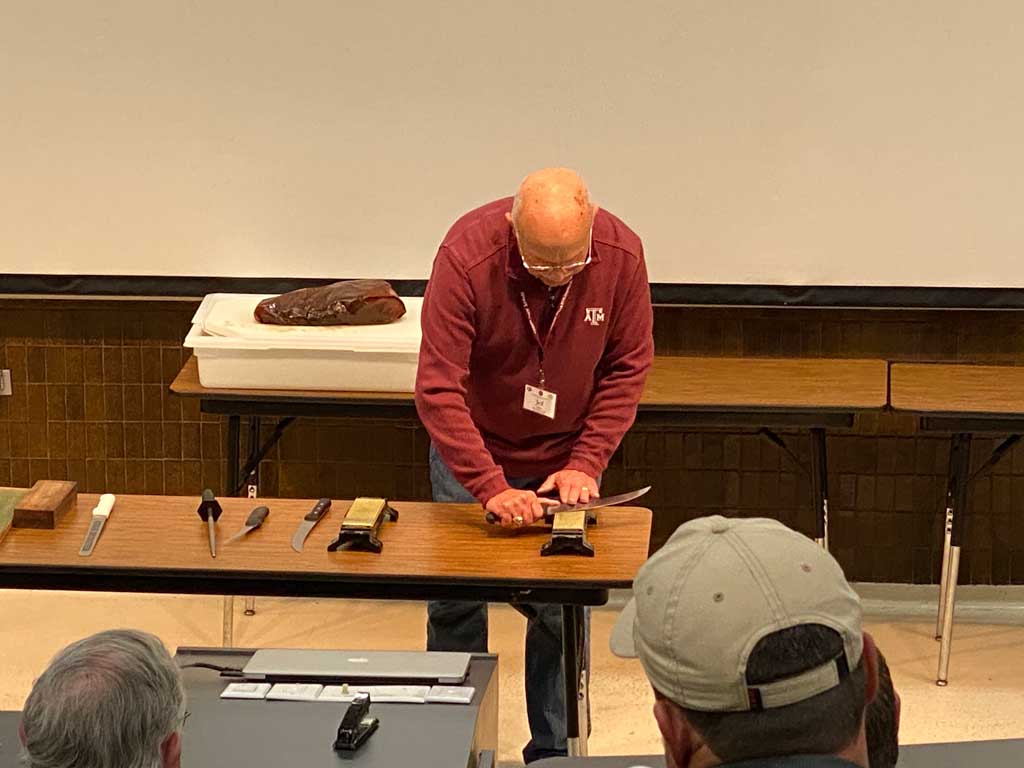

Knife Selection

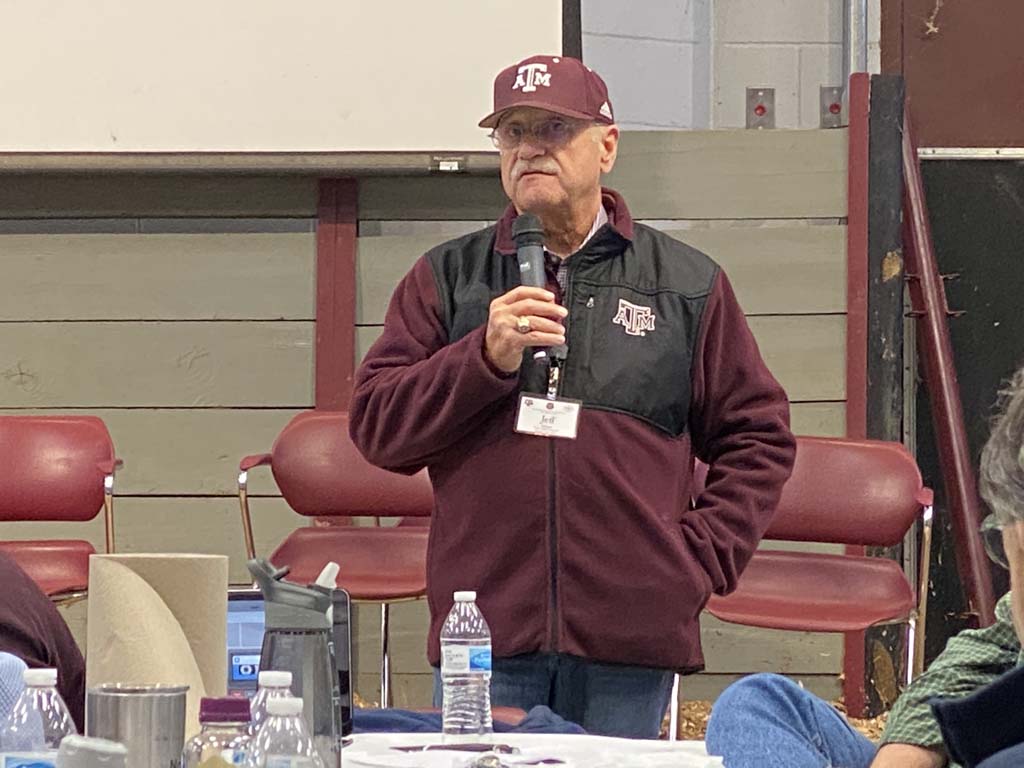

Dr. Jeff Savell led a brief discussion about knife selection, use, and sharpening. To summarize:

- Keep your knives sharp!

- Bigger = Better when it comes to brisket slicing knives.

Dr. Savell demonstrated how to sharpen and hone knives using a variety of stones, a steel, and a leather strop.

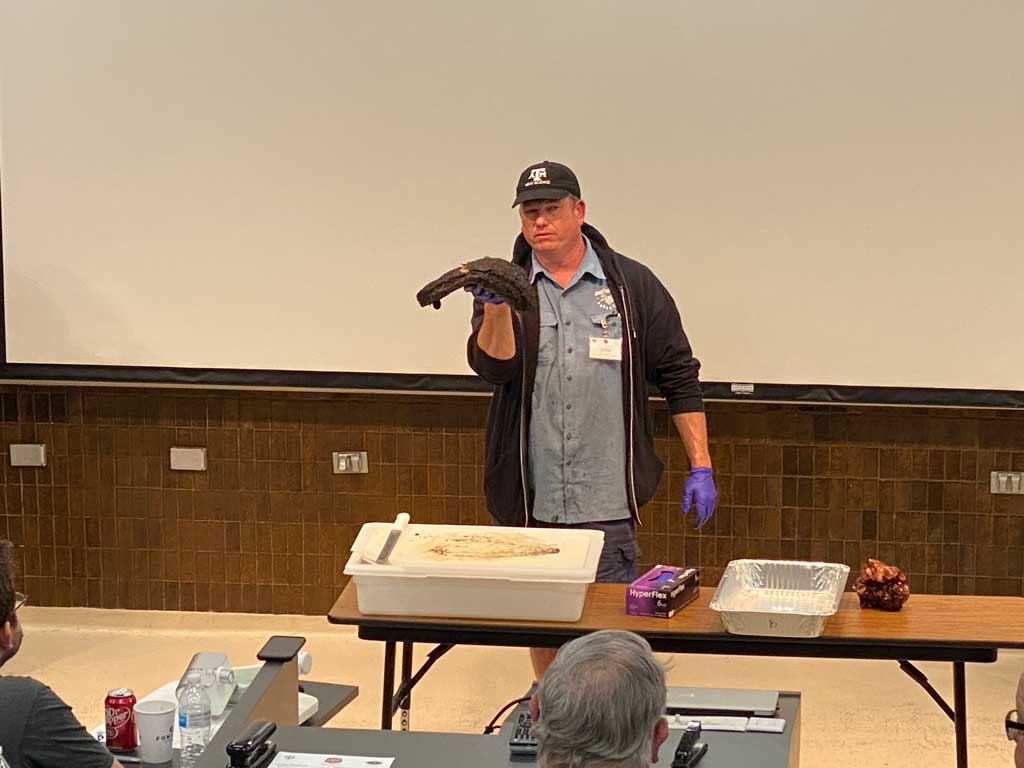

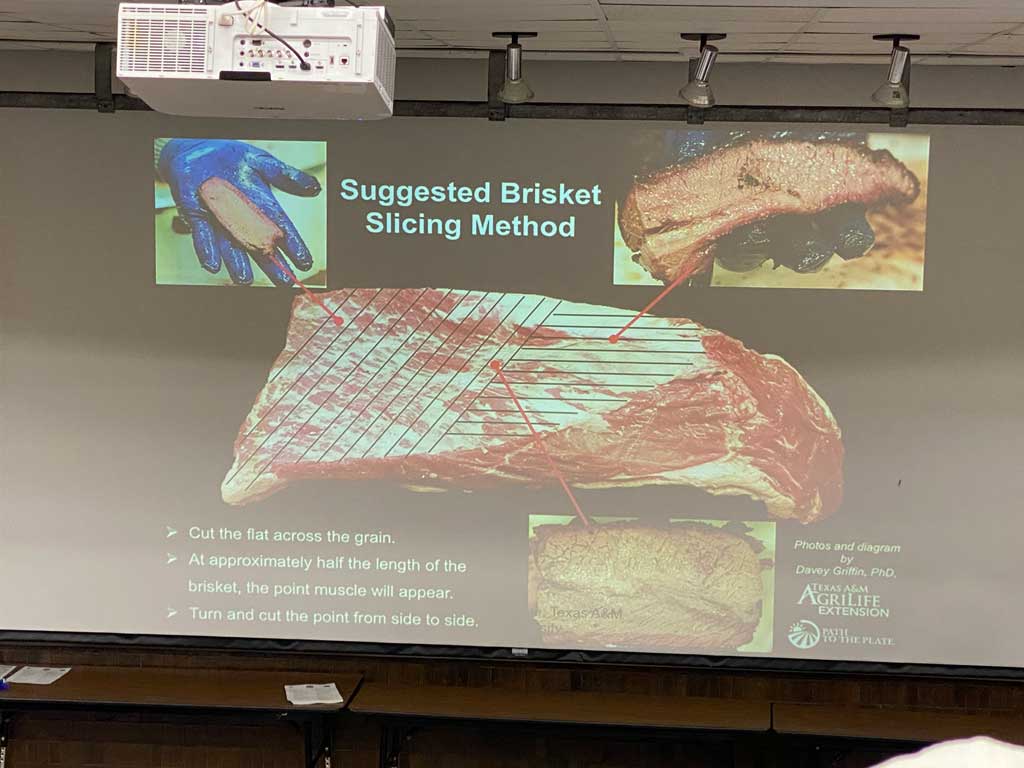

Slicing Cooked Brisket

This section was led by John Brotherton of Brotherton’s Black Iron Barbecue. He brought out a cooked brisket and showed the U-shape that a “relaxed”, properly cooked brisket should have. It should almost want to crack in half in the middle, and you can see that happening in this photo.

To begin, there was a short discussion about wrapping brisket in butcher paper. The suggestion was that most restaurants wrap briskets when they hit about 170°F internal temp. If you wrap at a lower temp, say 160°F, you end up with more hot liquid inside the paper at the end of cooking, which is a potential burn hazard.

Mr. Brotherton says he allows briskets to cool and then holds them at 145°F for several hours before slicing and serving. This particular brisket came off the pit at 7:30 AM, cooled for 2-3 hours, and was then held at temp until our demo at 12:55 PM.

Mr. Brotherton slices brisket flat about 1/4″ thick and brisket point about 3/8″ thick. He follows the Texas Turn method when slicing a whole brisket: slicing the flat across the grain until reaching the point, which is about half the length of the brisket, then turning the point 90° and continuing to cut the point across the grain.

Suggested brisket slicing method aka The Texas Turn

The ideal slicing temperature for brisket is 145°F. Holding the brisket high in the air in his gloved hand, Mr. Brotherton said, “If you can’t hold it in your hand, it’s too hot to slice.”

There was some discussion about how quickly the surface of sliced brisket oxidizes and dries out. When slicing, try to keep slices together in a group. If a chunk of cut brisket will be on the cutting board for a moment, turn it cut side down on the board if possible.

For backyard barbecuers, it’s suggested that when the brisket reaches your finished target internal temp, remove it from the cooker, allow the wrapped brisket to rest on the counter for about 45 minutes to stop the cooking process and bring down the temp, then place the wrapped brisket in an empty cooler to keep it in around 145°F and hold it for a couple of hours until ready to serve.

Taste Test Brisket Lunch: Different Grades Of Brisket

At Camp Brisket, you eat a lot of brisket. By the end of class, you may be sick of it…but only for a while. As Dr. Savell points out, “Don’t complain about too much brisket, you didn’t sign up for ‘Camp Salad’.”

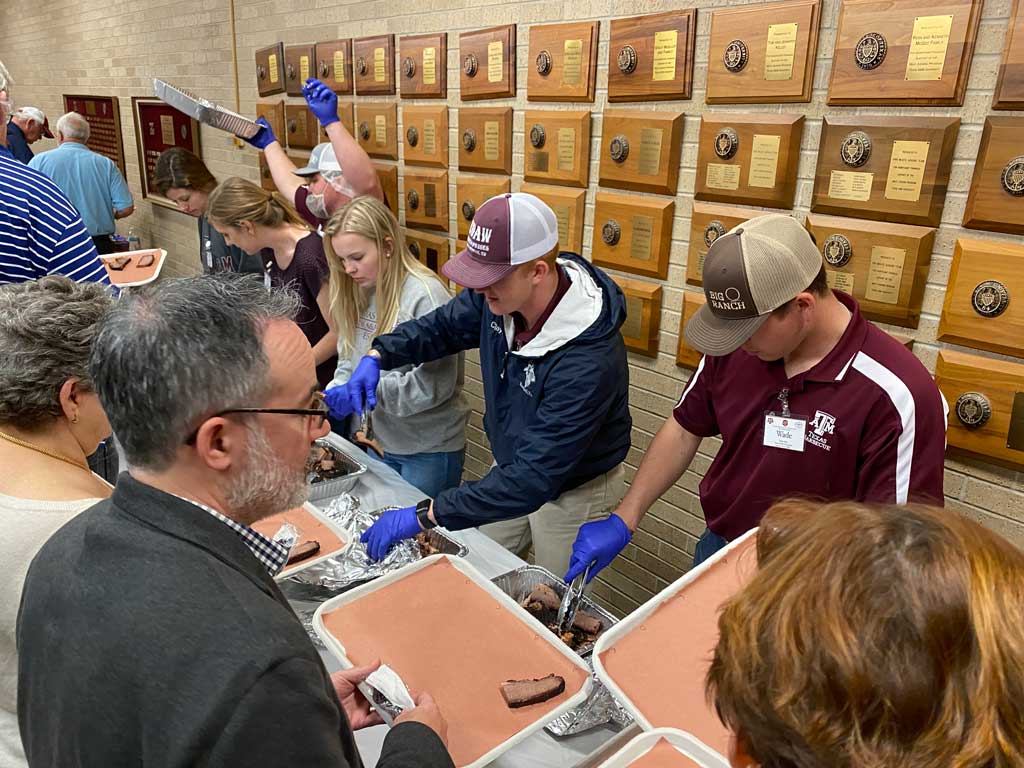

On Day 1, John Brotherton, Dominic Colbert, and Alanmykal Jackson from Brotherton’s Black Iron Barbecue and Alton Matthews of The Dawgfatha’s BBQ, working with Dr. Davey Griffin and a crew of TAMU students, prepared a slew of briskets for lunch.

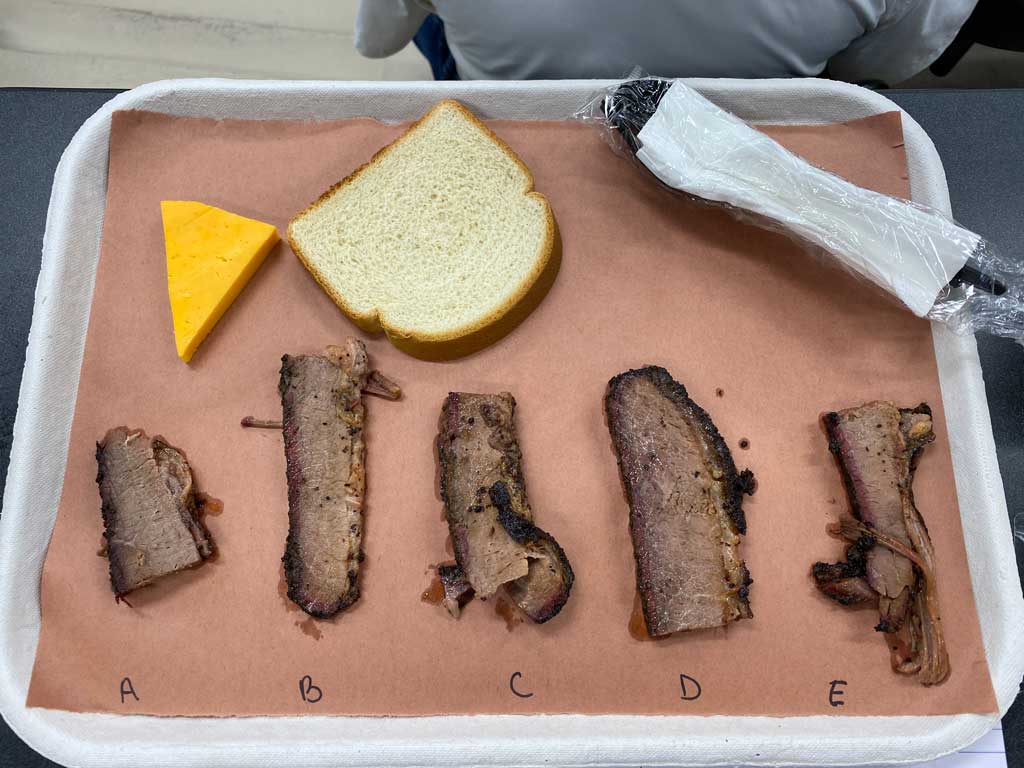

We were told that we would “evaluate briskets for tenderness, juiciness, flavor, and overall like/dislike.” We received a tray marked A through E and a sample of lean brisket for each letter. No sides were offered other than cheddar cheese and white bread (both common to Central Texas barbecue) and of course beverages. After sampling the briskets, we scored each on a scale of 1 to 9 for flavor, tenderness, juiciness, and overall like.

Day 1 brisket lunch taste test for quality grade. Left to right: Choice, Prime, Select, Texas Wagyu, Chairman’s Reserve Choice

What we were not told until after the scores were tabulated and reported was that these were different grades of brisket: Texas Wagyu, USDA Prime, Chairman’s Reserve (top tier of USDA Choice), USDA Choice, and USDA Select. All were trimmed to no more than 1/4″ fat, seasoned with 3/4 cup of a 50/50 mix by weight of Morton’s Kosher Salt and coarse-ground black pepper, cooked fat-side up over post oak logs in the same A.N. Bewley pit, wrapped in peach butcher paper, and rested.

The five briskets we tasted for quality grading. Left to right: USDA Select, USDA Choice, Chairman’s Reserve Choice, USDA Prime, Texas Wagyu

After the TAMU students crunched the numbers and ran the statistics, the overall “like scores” were:

A) Choice: 6.0

B) Prime: 6.2

C) Select: 5.7

D) Wagyu: 7.1

E) Chairman’s Reserve: 6.0

The Wagyu brisket was the overall winner. You’ll notice that while participants were able to discern differences between the grades of brisket in the order you would expect—ranking Wagyu highest and Select lowest—there was no statistical difference in scores between Prime, Chairman’s Reserve, Choice, and Select. We were told this was the same result as Camp Brisket 2019.

Beef Grading & Certified Beef Programs

With our bellies full of five types of brisket, it was natural to segue into the subject of Beef Grading and Certified Beef Programs. This discussion was led by Dr. Davey Griffin and Ray Riley, the Rosenthal Meat Center Manager.

As mentioned during “The Anatomy Of A Brisket” in the morning session, cattle are slaughtered, chilled for 36-48 hours, then optionally graded for quality by USDA inspectors paid for by the meat packer. There are many factors that going in the quality grading of beef. You can read about all of them at USDA Beef Quality and Yield Grades. Suffice it to say that marbling (the dispersion of fat within the lean) is the primary way beef quality is determined. Carcasses with the highest amount of marbling are graded USDA Prime. Carcasses with less marbling are graded USDA Choice; even less marbling USDA Select.

A cut is made between the 12th and 13th ribs to expose the ribeye muscle. The freshly exposed surface is allowed to “bloom” for 15 minutes, allowing the color of the meat to change from purple to bright red. The USDA inspector visually examines the amount and distribution of marbling in the ribeye muscle and decides on the grade (Prime, Choice, Select). Visual inspection can also be automated through the use of computer-controlled cameras that determine degree of marbling with the USDA inspector accepting or rejecting the computer’s recommendation.

Mr. Riley made the cut between ribs 12 and 13 on our carcass and showed us a series of photo cards that can be compared to the ribeye to help determine the degree of marbling.

At the morning break, we were able to step up to the side of beef and examine the marbling in the ribeye for ourselves.

Mr. Riley indicated this side of beef would probably grade as Choice with a modest amount of marbling.

Can Grass-Fed Beef Grade USDA Prime?

When asked about grass-fed beef grading as USDA Prime, Dr. Savell said there were some “shenanigans” going on. He didn’t say much more than that. We usually think of intramuscular fat (marbling) as the result of finishing cattle on grain at feed lots before slaughter. My independent reading on the subject tells me that it’s possible to get grass-fed beef that grades USDA Prime, depending on the genetics of the animal, but it may not be common.

Where Is All This USDA Prime Beef Coming From?

Having read the Serious Eats article Rethinking Prime Beef: Why “Choice” May Be Your Best Bet, I asked Mr. Riley if USDA Prime beef at Costco is just as good as USDA Prime beef from other sources. I also asked, “Where is all this prime beef coming from?” We’ve always been told prime beef amounts to only 2% of all beef production, yet now we find it in abundance at Costco and supermarkets. Mr. Riley explained the increased availability in basically the same way it was explained in the Serious Eats article—better genetics (genetic mapping, identifying genetic markers that correlate with better marbling), ranchers sharing information and raising cattle with better marbling, and consumer demand/market forces encouraging higher production. He indicated that different breeds take on fat development faster than others, that almost 10% of beef today grades as USDA Prime, and that despite breed the USDA Prime purchased at Costco should taste the same as prime purchased elsewhere.

Can You Make Good Barbecue With USDA Select Brisket?

There was discussion about the use of USDA Select briskets for barbecue, especially in light of the fact that Snow’s BBQ, the #1 barbecue joint in all of Texas according to Texas Monthly magazine in 2017, uses USDA Select briskets (and sometimes USDA Choice). Their success with select briskets is due to:

- Buying small briskets (7-8 pounds) that cook faster.

- Wrapping in aluminum foil about 2/3 of the way through the cooking process to retain moisture.

With USDA Prime briskets, you’ve got a larger margin of error to achieve a good result; with USDA Select briskets, you’ve got to be spot-on to get a good result.

About Branded Beef

Branded beef (e.g. Certified Angus Beef, Chairman’s Reserve) is beef that grades in the top tier of USDA Choice and sometimes includes the low end of USDA Prime. When buying branded beef, there is no guarantee that it will have more marbling that regular USDA Choice beef, but it may have more marbling.

About Wagyu Beef

Wagyu beef is all about the breed of cattle, not the USDA quality grade. There is a Japanese grading system for Wagyu beef that rates quality on a scale of 1 through 5 with 1 being “poor” and 5 being “excellent”. Wagyu cattle are breeds that historically accumulate a lot of intramuscular fat; they prefer fatty acids as their source of muscle energy.

Wood & Smoke Panel

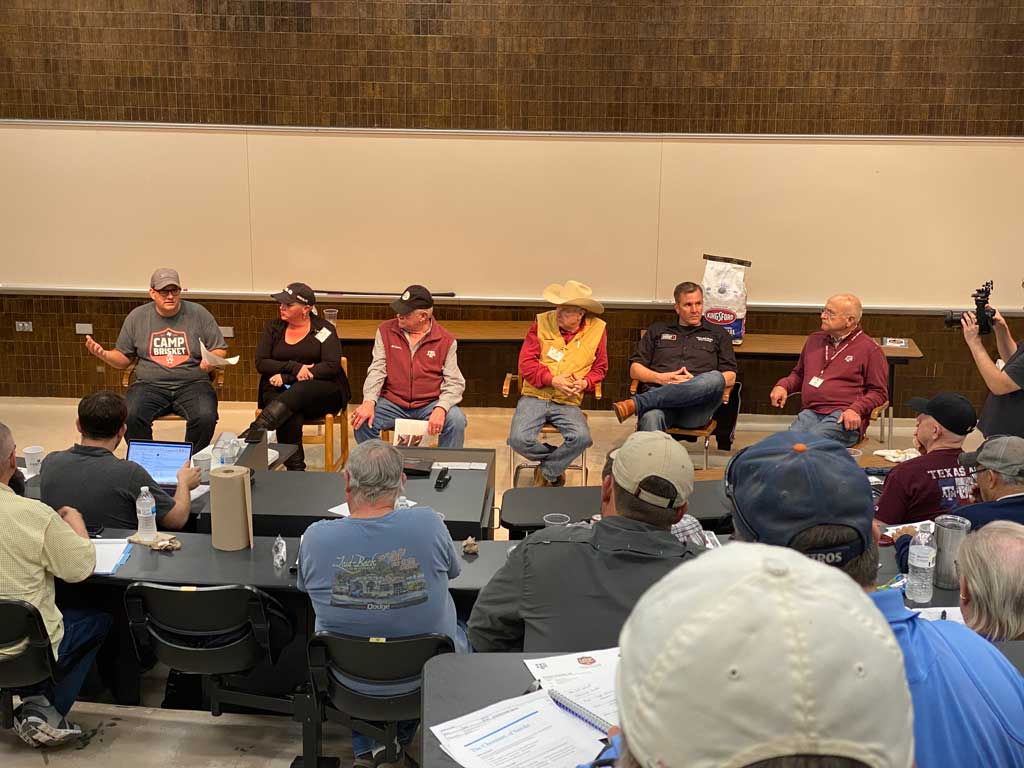

Wood and smoke panel. Left to right: Daniel Vaughn, Danielle Bennett, Dr. Nick Nickelson, Homer Robertson, Kevin Kolman, moderator Dr. Jeff Savell

This panel discussion featured Kevin Kolman, Dr. Ranzell “Nick” Nickelson II, Homer Robertson, Danielle Bennett aka Diva Q, Dr. Jeff Savell, and was moderated by Daniel Vaughn.

Dr. Nickelson spoke about the chemistry of smoke and seasoned wood. We’d spent much of the class up until this point discussing the complexity of meat; Nickelson said that smoke was also a topic of great complexity.

A wood fire cooks the meat; its smoke flavors the meat and has antimicrobial properties.

It’s important to use well-seasoned wood when barbecuing, in the range of 9-15% moisture content, especially in stick burners. A clean fire will impart the good aspects of smoke to your barbecue.

When burning green wood, much of the fire’s energy goes into driving off water content, and undesirable flavor compounds can result.

Dr. Nickelson demonstrated a handheld electronic wood moisture meter that he uses to check the moisture content of seasoned wood.

Post oak is commonly used for Central Texas barbecue, but pecan, hickory, and mesquite are used in other parts of the state, and there was some discussion about the pros and cons of these other woods. Regarding mesquite for smoking Texas barbecue:

- It burns hotter than post oak.

- If you damp down the vents on your pit, the fire can get dirty, thus the reputation of mesquite as being too strong.

- It’s often burned down into coals before use.

The panel discussion turned to wood chunks for smaller smokers like the Weber Smokey Mountain Cooker. Wood chunks are typically double-kiln dried to prevent disease transfer across state line. As a result, they may be drier than the 9-15% moisture content discussed for seasoned wood and thus will produce less smoke. There’s not a whole lot you can do about this, you get what you get when you buy wood chunks at retail stores, unless you buy wood chunks from online suppliers that can tell you the moisture content of their products.

Kevin Kolman described a method he’s been using in lieu of wood chunks in the WSM that he says gives him good results for Texas-style brisket. Kevin lays a 12″ long split piece of post oak across the bottom of the WSM charcoal chamber, fills the empty area around the wood with unlit Weber Charcoal Briquettes, pours a Weber chimney starter full of lit charcoal on top of everything, lets it burn for about 5 minutes, then assembles the cooker. He uses water in the water pan, sets all three bottom vents 1/4 open and the top vent 1/2 open.

There was a lot of discussion about wood pellets for pellet smokers. Danielle Bennett recommended Lumber Jack Grilling Pellets as a good quality brand. Kevin Kolman mentioned that Weber was coming out with their own wood pellet product.

A class attendee asked whether bark should be removed from smoke wood. The consensus seemed to be that there was no reason to do so, unless you see something really gnarly, rotten, punky, diseased, or infested. As Bryan Bracewell, owner of Southside Market & Barbecue, said from his seat in the audience about bark, “I bought it, I burn it.”

Adjourn For Day 1 & Dinner

As we wrapped up for Day 1, Dr. Savell commented that we’d covered a lot of ground and ended with this thought: When it comes to barbecue and brisket, we should worry about the big things, not the little things.

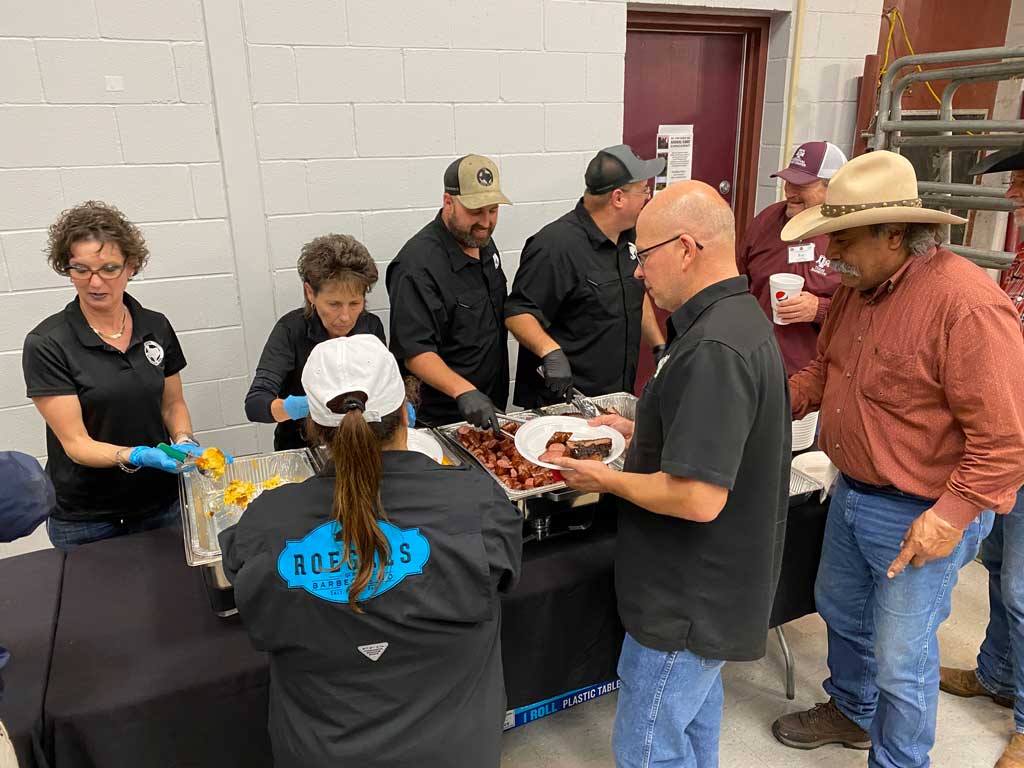

Around 7:00 PM, we reassembled for dinner at the TAMU Beef Cattle Center a short distance from campus. Brisket, sausage, and side dishes were prepared by Brad Doan & Family of 1775 Texas Pit Barbecue Catering in College Station, TX. Homer Robertson, world champion chuck wagon competitor, wrangled the desserts consisting of apple crisp and bread pudding. Saint Arnold Brewing Company providing beer and other refreshments and Fontana Coffee Roasters and R.C. Tortorice provided coffee and tea.

We had lots of good conversation and fellowship over some delicious brisket, but things were cut short at 9:00 PM by a tornado watch for Brazos County. Dr. Savell was friendly but forceful in his insistence that we retreat to the safety of our hotel rooms back in town before the storm arrived at 10:00 PM.

Overnight Brisket Cook

While most of us were comfortably ensconced in our hotel rooms, a few brave pitmasters hunkered down for the night at the TAMU Beef Cattle Center to smoke the briskets we’d be sampling for lunch on Day 2. At one point they took shelter in a small, windowless room during the height of the storm. It was so windy that rain was literally blowing horizontal to the ground through the cook area. Fortunately the pits and Homer Robertson’s chuck wagon did not blow away.

Briskets went into the pits on Friday night at 8:00 PM for lunch at noon on Saturday. Pits included five Weber Smokey Mountain Cookers, a Pitts & Spitts pellet grill, a Jambo stick burner, and two A.N. Bewley pits.

Day 2: Chuck Wagon Breakfast Around The Pits

Lots of strong wind, rain, and a few downed trees and power lines were the result of the overnight storm, but the worst of it was over by midnight. I got a good night’s sleep and we all reconvened at the TAMU Beef Cattle Center for Day 2 of Camp Brisket.

Things got started on Saturday at 7:30 AM with a hearty chuck wagon breakfast prepared by Homer Robertson and his crew. Breakfast tacos with a choice of chopped brisket or sausage, scrambled eggs, salsa, shredded cheese, and biscuits with gravy were on the menu.

Some of us ate outside around the pits, some went inside where it was warm to enjoy their breakfast.

Pit Discussion & Building A Good Fire

With breakfast out of the way, we bundled up and gathered outside in the pit area. We went from pit to pit, getting a short presentation about each and how a good fire is achieved in each.

Kevin Kolman discussed the five Weber Smokey Mountain Cookers, Ryan Zboril discussed the Pitts & Spitts pellet grill, Pat Reardon discussed his Jambo stick burner, and Larry Lewis discussed the two A.N. Bewley pits.

Pat Reardon discusses the operation of his Jambo pit

Barbecue Pit Design & Maintenance Panel

Barbecue Pit Design & Maintenance Panel. Left to right: Wayne Mueller, Arnis Robbins, Sunny Moberg, Ryan Zboril, Bryan Bracewell, moderator Dr. Davey Griffin

Back in the warmth of the TAMU Beef Cattle Center meeting hall, we moved on to a panel discussion of barbecue pit design and maintenance. Dr. Davey Griffin moderated the panel; panelists included Bryan Bracewell of Southside Market & Barbecue, Wayne Mueller of Louie Mueller Barbecue, Sunny Moberg of Moberg Smokers, Arnis Robbins of Evie Mae’s Pit Barbecue, and Ryan Zboril of Pitts & Spitts Smokers & Grills.

Each panelist described what kind of pits they preferred and how to get the most out of them. Wayne Mueller discussed the operating quirks of the old brick pits at his famous joint in Taylor, TX that have been in use since 1949. Bryan Bracewell discussed the importance of keeping the pit exhaust stacks clean, the grease fires that can occur, the sprinkler systems (and even garden hoses) used to knock down exhaust stack fires, and the differences in fire suppression requirements from one jurisdiction to another.

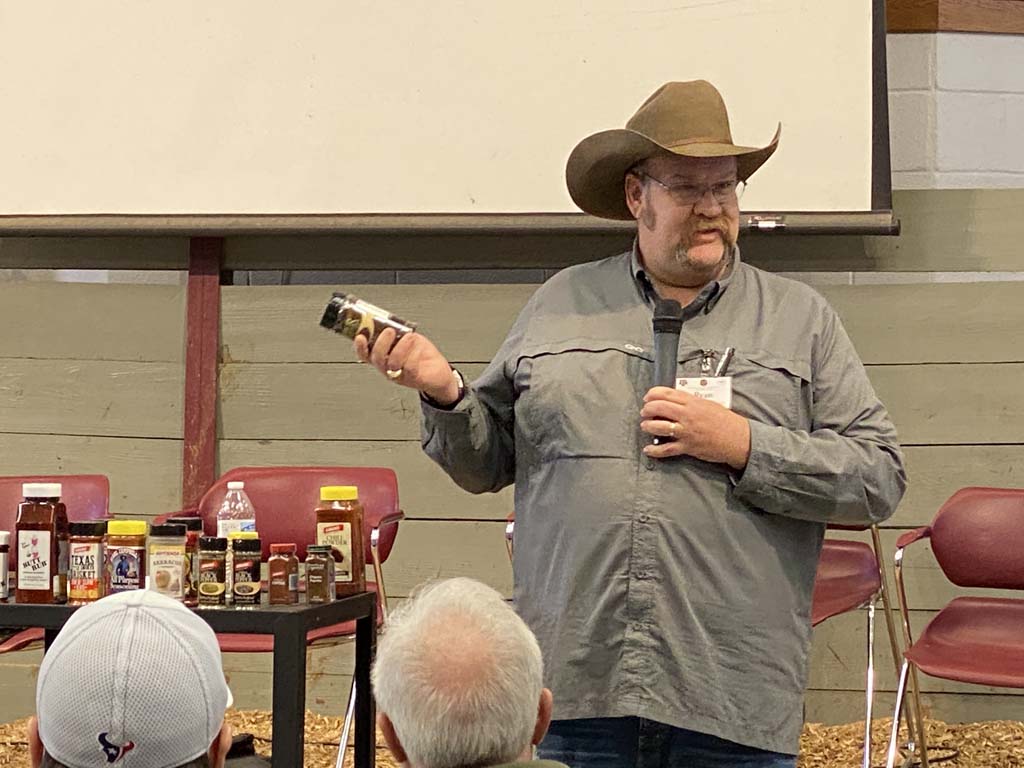

Seasonings Overview

Ryan Heger, senior food scientist at Adams Extract & Spice, gave us a rundown on the spices commonly used in barbecue rubs beside the usual kosher salt and pepper. Comments included:

- Buy spices from quality vendors.

- Buy spices from vendors with high turnover to get the freshest products.

- Buy spices in reasonable quantities you will actually use before they begin to lose their quality.

- Spices don’t really go bad, they lose flavor, aroma, heat, potency, etc.

- Store spices in airtight containers in a cool, dark location.

- Whole spices retain their quality longer than ground spices. Buy whole and grind your own when possible.

- We’re seeing a trend toward more international flavors and spices.

Taste Test Brisket Lunch: Different Smoke Woods

It’s 12:00 PM, time for lunch and more brisket! This time we received a tray marked F through I and a sample of lean and fatty brisket for each letter, along with the requisite cheddar cheese and white bread. We rated each sample as we had done on Day 1, using a scale of 1 to 9 to score each brisket for flavor, tenderness, juiciness, and overall like.

What we did not know until after the scores were revealed was that each brisket had been smoked using a different smoke wood. Here are the results for overall like:

F) Post Oak: 6.3

G) Pecan: 6.8

H) Hickory: 6.2

I) Mesquite: 6.8

Briskets smoked over pecan and mesquite were rated highest; post oak and hickory the lowest. When the numbers were crunched by the TAMU students, there was no statistical difference between pecan, mesquite, or oak.

According to Dr. Savell, participants at Camp Brisket 2019 had no differences in preference for the same four smoke woods. In most prior years, either oak or hickory were the winners.

The Science Behind Barbecue

With another belly-load of brisket consumed, it was time for Dr. Jeff Savell to give us a rundown on the science behind meat and barbecue, with some help from pitmaster Russell Roegels and TAMU alumnus, surgeon, and barbecue enthusiast Patrick Reardon.

Stress & Dark-Cutting Beef

Dr. Savell spoke about the effects of stress on cattle and their meat. The two most stressful times of year for cattle are October when the weather turns cold and July/August when the weather turns hot and cattle experience heat stroke. The stress they feel is most intense in the 2-3 days after such events.

Stress around the time of slaughter can result in “dark cutting beef”, meat that looks purple rather than cherry red. Dark-cutting beef occurs in 1 – 2% of beef carcasses. It affects the pH of the meat and results in more moisture retention. The processes that result in dark-cutting beef are explained in this article by Dr. Savell.

While dark-cutting beef sometimes slips into retail stores (you may see a package of four steaks in the supermarket, three bright red and one purple), it’s usually diverted to the foodservice industry where it’s cooked and processed and consumers never see the original dark color. The dark color and higher pH do not make the flavor of the meat unacceptable.

Why So Much Connective Tissue In Brisket?

The high degree of connective tissue in brisket is the result of bovine anatomy: cattle have no clavicles, or collarbones. The brisket muscles (the superficial and deep pectorals) must carry about 60% of the animal’s weight, and that musculature is held together and supported by a whole lot of connective tissue.

Relaxed Brisket Is U-Shaped

A “done” brisket is a “relaxed” brisket. When you pick it up in the middle, it should have a U-shape.

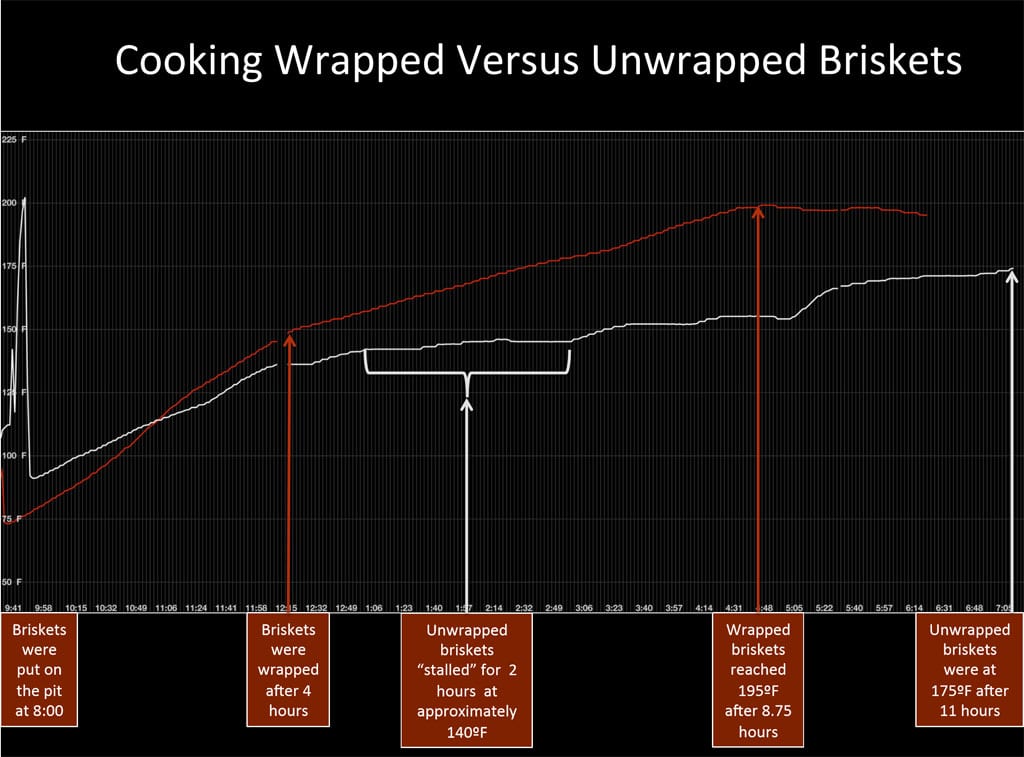

The Stall

The stall that we experience when cooking brisket is the result of evaporative cooling that occurs at the meat surface. Meat is 70% water, and as we cook brisket we’re driving off about 50% of its water content. There comes a point in the process, usually in the range of 140-160°F, where the internal meat temp stops rising. This is known as “the stall”, where the meat is essentially cooking and cooling at the same time. The internal temp does not start rising again until the surface of the meat dries out, then it proceeds to doneness.

You can beat the stall by wrapping brisket with aluminum foil or peach butcher paper once the internal temp reaches about 160°F. However, using foil can result in a pot roast flavor. Using peach butcher paper is said to be the better alternative as it is not air or water tight like foil and helps to get the brisket through the stall faster but without the pot roast flavor.

This graph from a Camp Brisket 2013 presentation shows the time and temperature progression for a test of wrapped and unwrapped briskets. You can read more about it here:

Brisket “Stall” Demonstrated During Camp Brisket 2013

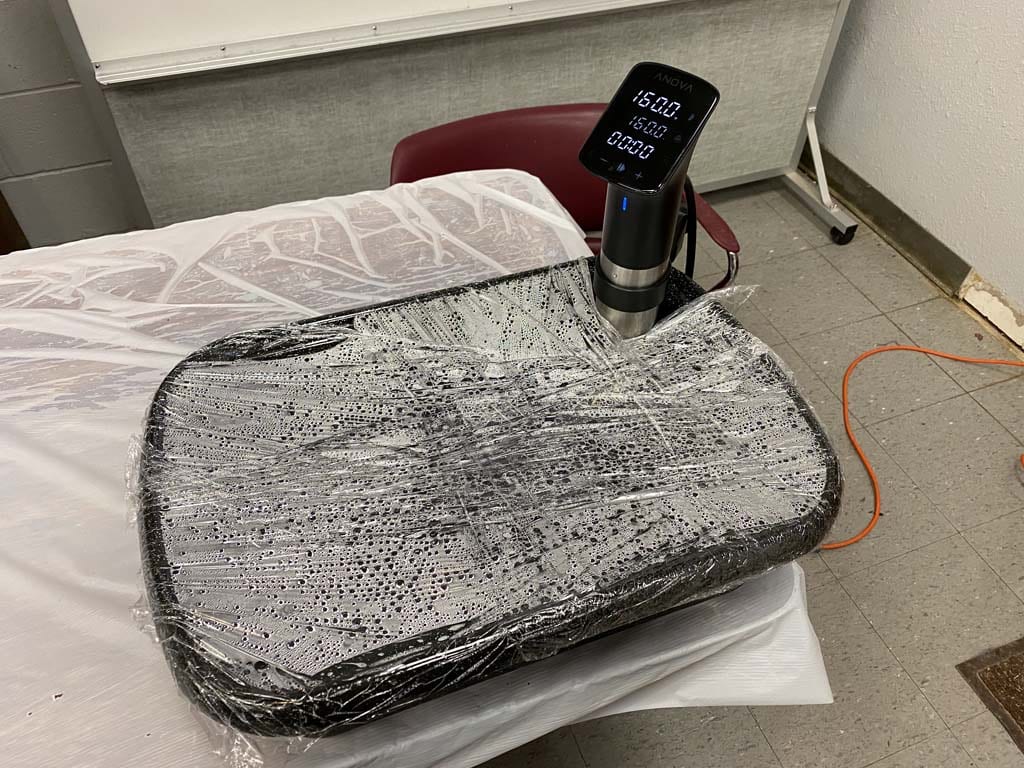

Using Sous Vide To Reheat Brisket

Patrick Reardon demonstrated the use of a sous vide machine to reheat a cooked brisket that’s almost as good as the original.

A cooked brisket is cooled to 130°F, blotted with paper towels, and wrapped with several layers of plastic wrap to prevent any sharp areas of bark from puncturing the vacuum bag. Refrigerate the brisket until cold then seal it in a vacuum bag. Now freeze the brisket, if desired.

To revive the brisket, set the sous vide machine to 160°F and place the sealed brisket in the warm water. A refrigerated brisket will take about three hours and a frozen brisket about five hours to reach 160°F, then can be held at that temp indefinitely until ready to serve.

Patrick says he usually puts the brisket into the sous vide about an hour earlier than described above, just for good measure. When his guests are ready for brisket, he removes it from the vacuum bag and by the time he begins slicing it’s down to a perfect slicing temp of 145°F.

Speaking from the audience, Danielle Bennett mentioned that ThermoWorks sells a sous vide kit that includes a thermometer, sous vide mini probe, and foam seals that let you measure internal meat temp through the vacuum bag without breaking the seal.

Life As A Pitmaster Panel

The final session of Camp Brisket was a panel discussion about life as a pitmaster. It was moderated by Dr. Jeff Savell; panelists included Bryan Bracewell of Southside Market & Barbecue, Wayne Mueller of Louie Mueller Barbecue, Arnis Robbins of Evie Mae’s Pit Barbecue, John Brotherton of Brotherton’s Black Iron Barbecue and pitmasters Dominic Colbert and Alanmykal Jackson, Todd David of Cattleack Barbeque, and Russell Roegels of Roegels Barbecue Co.

Each panelist took turns describing their thoughts and experiences of being a pitmaster—how they got to where they are, the challenges and rewards, and why they love the barbecue business. Some like Robbins and David have been in the barbecue business for less than 10 years; they’re building a business and a legacy. Others like Mueller and Bracewell are tending to a family legacy, Mueller’s going back to 1949, Bracewell’s a business that dates back to 1882 and founder William Moon. As Mueller put it at one point during his comments, he feels the pressure of keeping the business going that was started by his grandfather and run by his father and not screwing it up!

Bracewell commented on how something you start doing for the love of it can end up being a job, can end up being work, and how that makes you feel inside. He said, “I just wanted to make barbecue. What happened to that?” He now spends his days managing a business, hiring staff, and doing everything other than being a pitmaster and actually making barbecue. Bracewell hopes to be able to turn the business over to his young son Chase someday.

Life As A Pitmaster Panel. Left to right: Russell Roegels, Todd David, Arnis Robbins, Bryan Bracewell, Alanmykal Jackson, Dominic Colbert, John Brotherton, Wayne Mueller, moderator Dr. Jeff Savell

There was some discussion about turning points in business. Being listed as a top barbecue restaurant in Texas Monthly magazine, being reviewed positively by Daniel Vaughn or by one of the big Texas newspaper food writers, or appearing on an episode of Diners, Drive-In & Dives or Man Fire Food can catapult your business to a whole new level. One of the panelists commented that you can always tell when your episode on one of these shows re-runs because the sales of the menu items featured on the show jump dramatically!

One theme that was commonly expressed by the panel was feeling blessed to be doing what they’re doing, and that they try to do their best every day. Said one panelist, “No one wakes up everyday trying to be 2nd place.”

What TAMU Has Learned Through Camp Brisket

Dr. Savell closed Camp Brisket 2020 by thanking us for attending, wishing us safe travels home, and noting how interesting it was that all of us from so many different places and walks of like would come together to bond over and learn how to tackle brisket!

He also summarized what he believes the Meat Science program at TAMU has learned through all the years of hosting Camp Brisket.

- The importance of choosing good quality products and ingredients from good sources, e.g. Wagyu and USDA Prime briskets.

- Size of brisket is not as important as proper cooking technique. You can use 7-8 pound USDA Select and Choice briskets and with the right cooking technique be named the #1 barbecue restaurant in Texas.

- How to properly trim fat and shape briskets so they’re “aerodynamic.”

- How to use seasonings to compliment the brisket.

- The importance of knowing your pit.

- Pitmasters should consider wrapping briskets as part of the cooking process.

- Let briskets cool a bit after hitting the target internal temperature, then hold at temp for several hours before slicing.

- Slice brisket when it’s 140-150°F internal temp. If the meat is too hot to hold in your hand, it’s too hot to slice.

Dr. Savell said that holding brisket for several hours before slicing is one of the most significant learnings of Camp Brisket and greatly improves the quality of your finished product.

Taste Test Brisket Dinner: Wrapped & Unwrapped

If you weren’t already tired of brisket, there was one last chance to sample it at the end of Camp Brisket. We were offered two samples, one wrapped in butcher paper during cooking, one unwrapped. I didn’t try these briskets and I didn’t see too many classmates trying them, either. I didn’t see any ratings scores but I’ve read that in past classes there was no significant difference in “overall like” scores for the two briskets.

Leftovers

Here’s some other stuff pertaining to my visit to Camp Brisket.

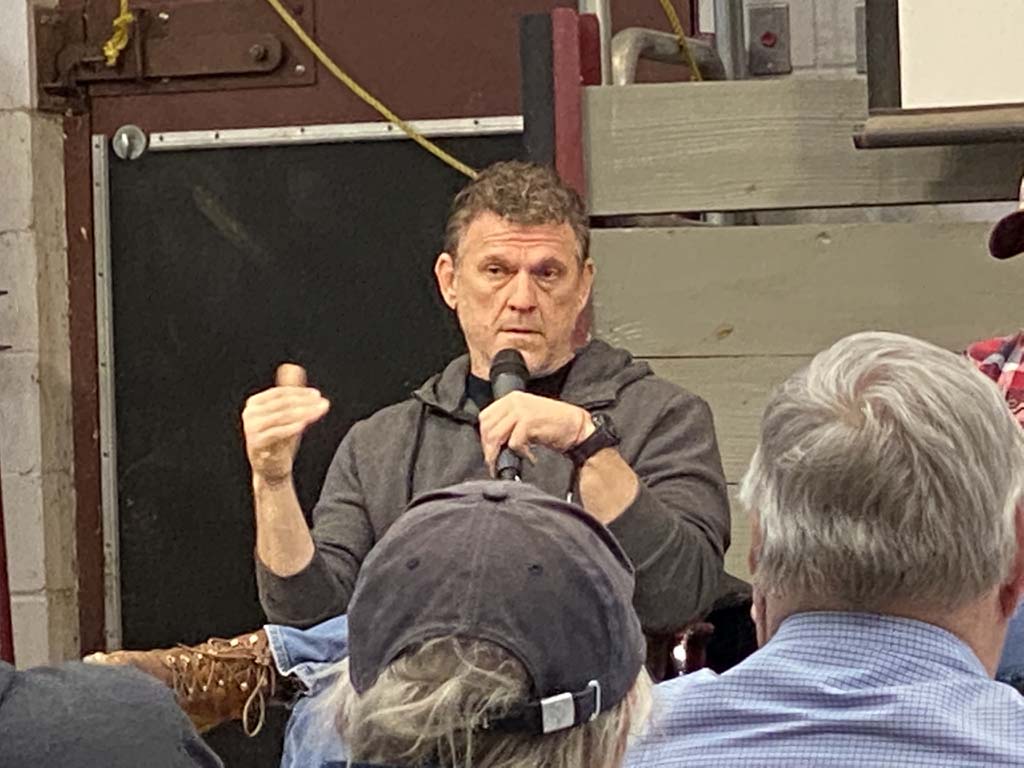

Meeting Daniel Vaughn

It was a real pleasure to meet and talk with Daniel Vaughn, the BBQ Editor of Texas Monthly magazine and author of The Prophets of Smoked Meat: A Journey Through Texas Barbecue. I greatly admire his work and I hope we can meet to enjoy some Texas-style barbecue in the San Francisco Bay Area sometime in the future.

Meeting Homer Robertson

Homer Robertson, World champion chuck wagon cook-off winner and Assistant Chief, Fort Worth Fire Dept.

Homer Robertson is a world champion chuck wagon cook-off winner and Assistant Chief, Fort Worth Fire Dept. In the same way that competition barbecue teams pack up their rigs and compete for cash and trophies based on a set of established contest rules, so too does Homer but in the realm of authentic chuck wagons and chuck wagon cooking. At his contests, he can only operate with equipment and ingredients that would have been available to chuck wagon cooks back in the day. You’ll never meet a nicer guy, the tornado warning didn’t phase him or his setup, and he came through on the biscuits and gravy for breakfast.

Texas A&M Rosenthal Meat Center

Just outside the Camp Brisket Day 1 classroom was the Texas A&M Rosenthal Meat Center retail meat shop. If I had drive to Texas in a refrigerated delivery truck, I would have loaded up on great looking fresh and frozen meats. I opted instead for the award-winning beef jerky, which was salty and loaded with black pepper and absolutely delicious.

USDA Establishment Lookup App

If you’ve ever seen these labels on packages of meat and wondered what they are:

…there’s an app for that! The USDA Meat, Poultry & Egg Product Inspection (MPI) Directory lets you enter the establishment number shown on the label to find out which company made and packed the meat product. Often times, the brand on the label is not the same as the company that made and packed the product.

Note: This app is unavailable in the Apple App Store as of August 2021. Hopefully it returns soon!

For example, this Dickey’s Polish Sausage that I found at Walmart is made at Establishment 4800. The app says that’s Eddy Packing Co. in Yoakum, TX, along with their mailing address and phone number.

The Long Drive To College Station And Back

My wife and I decided to drive from California to College Station, TX so I could attend Camp Brisket, and it took us three days to get there and three days to drive back.

On the first day, we drove from San Jose to Tucson, stopping for dinner at Rudy’s “Country Store” Bar-B-Q in Goodyear, AZ. On the second day, we drove from Tucson to Austin, stopping for lunch at Whataburger in El Paso. On the third day, we enjoyed lunch at Micklethwait Craft Meats in Austin, the #8 barbecue joint in all of Texas according to Texas Monthly magazine in 2017, then drove the last 2 hour stretch to College Station. There we explored the campus of Texas A&M University to find the building where Camp Brisket would be held, and we visited the George Bush Presidential Library & Museum.

Before leaving College Station, we stopped at the nearest H-E-B supermarket to check-out the awesome brisket section in the meat department. You can buy Wagyu briskets at the supermarket—unbelievable. While I had no way to get one back to California, I did pick up some Dublin sodas.

Heading home, on the first day we drove from College Station to Amarillo, stopping in Fort Worth for lunch at In-N-Out Burger and for gas and Beaver Nuggets at the world-famous Buc-ee’s convenience store. On the second day, we drove from Amarillo to Williams, AZ, stopping at the Cadillac Ranch just outside Amarillo and having lunch at Standard Diner in Albuquerque, a joint featured on Diners, Drive-Ins and Dives. On the third day, we drove from Williams to San Jose, having lunch at one of the largest In-N-Out Burgers I’ve ever seen in Barstow, CA.

A Texas-Sized “Welcome”

At the start of Camp Brisket, we were greeted by Dr. Jeff Savell with a big, loud “Howdy!” Most in the audience knew what to do and responded with a big “Howdy!” right back. Turns out I had just witnessed something special at Texas A&M University.

From the TAMU website on Aggie Terminology:

“Howdy” is the official greeting of Texas A&M. Students greeting one another — and especially campus visitors — with a “howdy” has earned the university a reputation as the friendliest campus in the world. The origins of this tradition are unknown, but it is one that Aggies proudly continue.

A Texas-Sized “Thank You”

An event like this doesn’t happen without the hard work of a lot of people. Special thanks to Marvin Bendele of Foodways Texas, Texas A&M University meat science educators Dr. Jeff Savell, Dr. Davey Griffin, and Ray Riley, and the many graduate students, undergraduate students, and staff that helped make Camp Brisket run smoothly for all of the attendees. They really made us all feel welcome at TAMU.

More Brisket Links On TVWB

- Brisket – High Heat

- Brisket – Smoked & Oven Finished

- Brisket – Midnight Cook

- Brisket – Wet Rub

- Whole Brisket – Central Texas Style Butcher Paper

- Whole Brisket – Competition Trim

- Brisket Flat – Central Texas Style Butcher Paper

- Burnt Ends – Kansas City Style

- Burnt Ends – Smoky, Sticky, Sweet

- Pastrami – Dry Cured

- Quick Pastrami – Smoked Corned Beef Brisket

- Brisket Servings Calculator

- Brisket Selection & Preparation

- Separating Brisket Flat & Point

- Using An Electric Oven To Hold Brisket At Temperature