April 9, 2006

In this topic:

Page 1

- Purpose Of My Visit

- Purpose Of This Article & Disclosures

- About The Clorox Technical Center

- The Briquette Pilot Plant

- The Climate-Controlled Charcoal Storage Room

- The Weber Burn Room

- The Division Lab Burn Room

Page 2

- The Kingsford Testing Protocol

- Old Versus New Kingsford Temperature Curve

- WSM Minion Method Temperature Curve

- My Minion Method Demo

- Using New Kingsford For Low & Slow Barbecue

- What’s In The New Kingsford?

- How New Kingsford Works

- Common Complaints About Kingsford

- Miscellaneous Items

- More Information About New Kingsford

- More Kingsford Links On TVWB

The Kingsford Testing Protocol

It’s impossible for Kingsford to replicate in a lab setting the conditions you experience in your own backyard. In fact, variables like weather, different methods of lighting briquettes, different types and quantities of meat, different types of cookers, etc. make it impossible for them to perform scientific tests that can be conducted again and again with any degree of accuracy.

Instead, Kingsford evaluates charcoal products head-to-head with a standard testing protocol that uses a measured amount of charcoal, a measured amount of lighter fluid, and a certain volume of airflow through the lab for ventilation.

Kingsford would not disclose the amount of charcoal burned in each test, but it is measured by weight. They did acknowledge that when testing the new product, they now use 90% of the weight they used for the old product.

During each burn test they measure the following attributes:

- Ease of ignition/visual ashing

- Length of time to be ready to cook at 380°F

- Length of time the fire remains above 380°F

- Maximum temperature achieved

Kingsford considers 380°F to be the starting point of high-temperature grilling. A burn test is considered complete when a charcoal is no longer able to sustain a temperature above 380°F.

This test is run multiple times (sometimes hundreds of times) for a particular product and the results are averaged. The final result is a curve showing temperature over time.

Kingsford has been using basically the same testing protocol for over 30 years. As a result, they have amassed a huge body of data about the performance of the old Kingsford product.

To compare a new product formula or a competitive product against the old Kingsford, the lab runs the test multiple times against the new formula or competitive product, averages the results, and compares its temperature performance curve to that of old Kingsford. They also compare performance data collected using proprietary technology which I saw but am unable to disclose.

Keeping the test equipment and lab in top shape is another aspect of achieving reliable results. The temperature equipment in both labs is recalibrated on a regular basis for accuracy, and the ventilation through the labs is measured and adjusted as necessary to create the same environment from day to day.

Old Versus New Kingsford Temperature Curve

This chart provided by Kingsford compares the stress test temperature curve of old and new Kingsford. It is based on 16 burn tests for each product using the standard testing protocol described above. The axis across the bottom is time in minutes; the axis on the left is temperature in degrees Fahrenheit—but Kingsford will not disclose the values on this axis for proprietary reasons.

Notice that the new product curve is above the old product curve at almost every point during the test.

It is based on this curve that Kingsford makes the following claims about the new product:

- 38% improvement in lighting time

- 22% improvement in the time it takes to get ready for cooking

- 13% increase in cooking time at a temperature over 380°F

Remember that these claims are based on lab testing. Your mileage will vary depending on an infinite number of variables in your own backyard.

WSM Minion Method Temperature Curve

You probably noticed that Kingsford’s standard testing protocol is geared towards grilling, not “low and slow” barbecuing. This shouldn’t surprise anyone; after all, most people that purchase Kingsford use it for high-temperature grilling.

When the R&D staff read the negative comments about new Kingsford on The Virtual Weber Bulletin Board, they tried to learn for themselves how we use their product in the WSM. They purchased two WSMs and followed the Minion Method instructions on this website. Kelly even took a WSM home for an overnight pork butt cook in his backyard. (I imagine he told his wife, “Really, honey, it’s for work!” Don’t you wish you could say that to your spouse?)

This chart provided by Kingsford compares the Minion Method in the WSM for the old and new Kingsford. It is based on averaging the results of six burn tests for each product in the lab.

For each test, Kelly lit 20 briquettes in a chimney, spread them over a full charcoal chamber of unlit briquettes, assembled the cooker, filled the water pan, and started with all vents wide open. Temperature was measuring by computer using a single thermocouple attached to the top cooking grate and passed under the edge of the lid.

When the cooker reached about 215°F, Kelly began damping down the three bottom vents to stabilized the cooker at about 235°F. The top vent remained 100% open throughout each test. The cooker was allowed to burn unattended overnight at the end of each business day. No more water was added to the pan after the initial load.

Note that these are Kingsford’s results, not mine, so I cannot vouch for the accuracy of the information. They reflect lab testing conditions—no meat, no stirring of ashes to rejuvenate the charcoal, no replenishment of the water pan, or any other variables you might experience in your own backyard. I will let this graph speak for itself and you can draw your own conclusions about the performance of the two products.

My Minion Method Demo

One of the reasons Kingsford invited me to visit was to make sure they were doing the Minion Method right, so they asked me to demonstrate it for them.

Using the new Kingsford Charcoal Briquets with Sure Fire Grooves, I counted out 20 briquettes into a Weber chimney starter, arranged them in a pile against one side of the chimney, and lit them with a Weber FireStarter lighter cube (that I brought with me) placed on the charcoal grate.

After about 10 minutes, the coals at the bottom of the pile looked like they were going well and the ones on top were just starting to ignite. I moved the chimney to the floor and filled the charcoal chamber to the top with unlit Kingsford. I spread the hot coals over the unlit ones, placed three large chunks of cherry wood (that I brought with me) in contact with the hot coals, assembled the cooker, and filled the water pan with cool tap water. I put the lid on the cooker and made sure the top vent and all three bottom vents were 100% open.

We monitored the cooker temperature on the computer for about 30 minutes. When it reached 200°F, I adjusted each of the three bottom vents to 25% open and the cooker settled in at about 230°F. Over the next hour or so, the temperature eased up to about 237°F, so I closed two of the bottom vents completely and left the remaining vent 25% open. This is how the cooker remained when I left at 2:00pm, and it continued to run this way for the rest of that day and into the next morning.

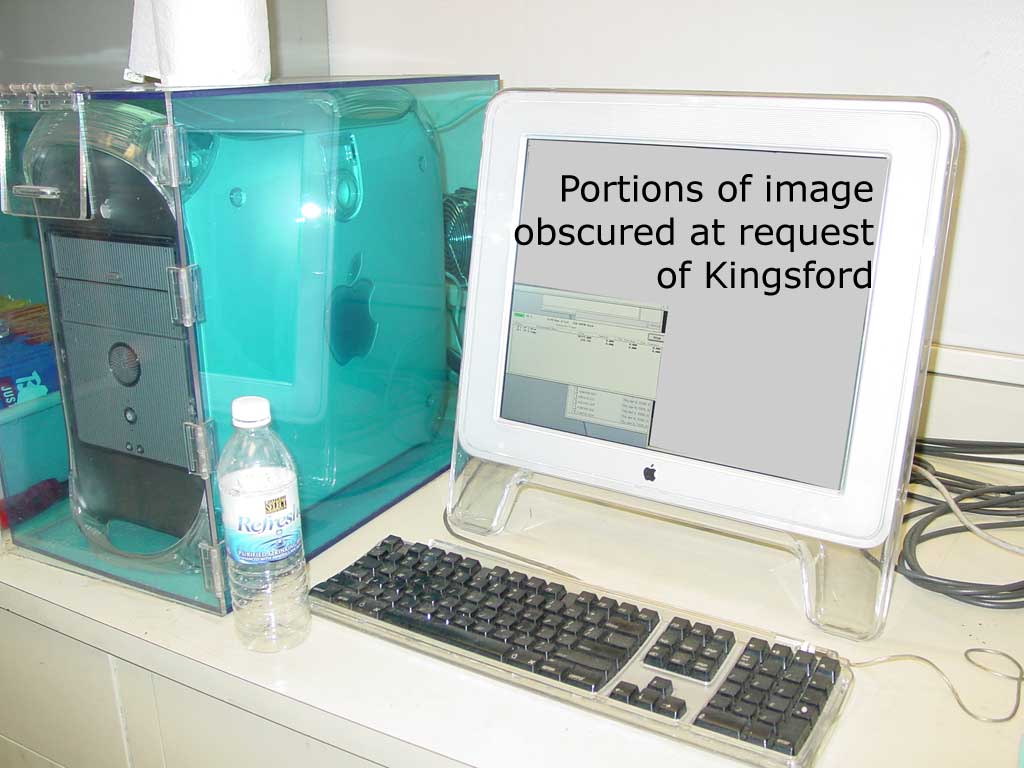

This computer tracked WSM temperature in the window at the lower left of the screen. Areas showing proprietary technology have been grayed-out on the monitor. The blue plastic enclosure helps protect the computer from dust and ashes.

The good news is that my demonstration of the Minion Method was basically the same as Kelly had been doing it himself in the lab and in his backyard prior to my visit.

This chart provided by Kingsford shows the results of my Minion Method demonstration. The axis across the bottom is time in hours; the axis on the left is temperature in degrees Fahrenheit.

You’ll notice that up to about 18 hours the curve is similar to the Minion Method curve shown in the previous chart. After that, Kelly started knocking ash off of the coals, something he hadn’t done in earlier tests.

Using New Kingsford For Low & Slow Barbecue

Bags of new Kingsford are the same physical size and contain approximately the same number of briquettes as before. Since the volume of both products is the same, you should continue using the same volume of new Kingsford in the WSM as you did before. For example, if you used a heaping-full charcoal chamber of old Kingsford in the past, you should try using the same amount of new Kingsford.

We spent some time discussing the difficulties that people were writing about on the bulletin board. It turns out that professional Kingsford customers were also reporting similar concerns.

For example, The Weber Grill restaurants in Illinois reported shorter burn times with the new product. The R&D staff flew to Chicago to see the process firsthand. It turns out that the chefs were lighting chimneys full of new Kingsford on a gas burner for the same length of time as they had always done with the old product. Since the new product lights faster, they were burning up a lot of the fuel before dumping it into their grills. By shortening the length of time on the burner and dumping the coals into the grill sooner, the chefs were able to achieve the burn times they wanted.

Another example was a Chicago restaurant where customers grill their own steaks over a low brick enclosure. In the afternoon before the restaurant opened, they emptied several 24-pound bags of old Kingsford into a long pile and lit some briquettes in two rows across the width of the pile. Those coals would burn toward the center of the pile and eventually meet, as well as burn the opposite direction toward the ends of the pile as the evening progressed. The restaurant manager complained that the new product did not last as long as the old product, but they found that by starting the fire later in the afternoon, they got the burn times they had been accustomed to.

In both cases, the problem was letting the new charcoal burn too long before actually starting to cook.

Based on these experiences, plus some experimentation with the WSM and Minion Method in the testing lab, Kelly has the following recommendations for using the new Kingsford for “low & slow” cooking in the WSM:

- Start with fewer hot coals to begin with. For example, if you normally start 20 briquettes of the old Kingsford, try using only 10 or 15 of the new product.

- These 10-15 briquettes will light faster than the old ones, so watch them carefully and place them on the unlit charcoal sooner than with the old product.

- Close the bottom dampers more than you would have with the old Kingsford, and do so earlier in the process to keep the temperature under control.

What’s In The New Kingsford?

This was one of the first questions I asked at the beginning of my visit. I reminded Bob and Kelly that Kingsford used to give out this information to consumers who asked, and that since food was cooked over the product, it only seemed reasonable that people should know what was in it. Despite my best efforts, Bob would not give me the ingredient list for the new product. In fact, he said that he didn’t know why the company had ever divulged the ingredient list in the past.

Bob acknowledged that wood char is the most abundant ingredient in the new product and that more wood char is being used in the new product than before. He said this change has resulted in better product performance and a higher manufacturing cost. He also said that when burned in equal volumes, the new product should produce about 10% less ash because it weighs 10% less than the old product and because it contains more wood char.

To see the ingredient list for the old Kingsford product and the purpose of each one, read the All About Charcoal article. It will give you a good idea of what’s probably in the new product.

How New Kingsford Works

Kingsford experimented with a variety of briquette sizes and shapes to create a faster lighting briquette. In the R&D lab I saw several prototype press rolls, some that made great big briquettes, some that made very small ones, and some that made different shaped impressions in a briquette. Lab testing showed that some designs worked while others did not.

These press rolls represent just a few of the experiments with different briquette sizes, shapes, and impressions to produce a new product that lights faster than the old one.

Ultimately, the old briquette size and shape with the addition of two parallel grooves in one side was chosen. These grooves create more surface area on the briquette, more edges where the briquette can catch fire, and more air circulation between briquettes.

Prototype grooved briquettes using the old product formula were sent to a number of consumers for field testing. Consumers reported that the prototype certainly lit faster, but they did not discern any difference in burn time, even though the addition of grooves resulted in a slight increase in burn time that could be measured in the test lab.

So Kingsford began working on different product formulas, ultimately deciding to add more “high quality ingredients”, most notably wood char, to give the new product a longer burn time that was both measurable in the test lab and noticeable to consumers.

Common Complaints About Kingsford

I talked with Bob and Kelly about the three most common complaints I hear about Kingsford.

Smell

Some people find the smell of burning Kingsford to be objectionable, especially during the early stages of lighting. The word “ammonia” is often used to describe the smell.

Bob said there’s no ammonia in the product and nothing that would produce ammonia during lighting or burning. Charcoal briquettes give off all sorts of compounds when burned, including sulfur oxides (SOx), nitrous oxides (NOx), volatile organic compounds (VOCs), and gases that have no taste or odor like carbon monoxide (CO) and carbon dioxide (CO2). Bob suggested that perhaps it was the SOx and some of the VOCs coming off the fire in the early stages of lighting that people find objectionable. However, as the fire intensifies, the heat of the fire consumes some of these compounds, which explains why the smell diminishes once the fire gets going.

My reading on the Internet about SOx indicates that it has a strong, pungent, stinging odor, so perhaps it is the major culprit. I’ve also read that burning raw wood releases all of the compounds listed above plus more. Lump charcoal has many of these compounds burned away during the charring process, which explains why it has less smell when burned than a charcoal briquette that contains sawdust and other heat-producing ingredients like Kingsford.

As a follow-up, I asked if there is a coating or a layer on the outside of a Kingsford briquette that smells funny at first, but then burns away with time. The answer is no. The product is continuous through and through.

Ash Production

The amount of ash produced by Kingsford during long cooking sessions can be a problem for some brands of cookers with limited ash-holding capacity. Some people object to the volume of ash for a variety of other reasons not related to cooker performance.

Since we could not discuss ingredients, we were not able to discuss the specifics of why Kingsford produces the amount of ash it does. However, since the new product weighs 10% less than the old product and because it contains more wood char, it should produce about 10% less ash when burned in the same volume as old Kingsford.

“Naturalness”

Some people object to Kingsford because they believe it is not as “natural” as other products. Sounding like my high school chemistry professor, Bob said, “There’s not much in this world that isn’t natural.” He insisted that each ingredient in Kingsford is safe and is added to serve a specific purpose that contributes to product performance. “So you’re not disposing of toxic waste in these briquettes?” I asked, tongue in cheek. “No,” answered Bob…very seriously.

Bob and Kelly expressed no health or safety concerns about using Kingsford in a continuous burn process like the Minion Method, nor does the Material Data Safety Sheet for Kingsford charcoal posted on The Clorox Company website.

Miscellaneous Items

Consistency between different source woods

I asked how Kingsford produces a consistent product nationwide given that each factory uses local wood varieties from the region where it is located. Kelly said that the extent to which a wood is charred greatly influences its performance characteristics. By varying the extent of charring for each type of wood, Kingsford produces wood char that meets certain performance criteria that allows them to manufacture a consistent product. Quality assurance testing of production samples in the lab ensures that Kingsford purchased in Maine or California both perform within the same standards.

Chinese Kingsford

I asked about the Chinese Kingsford product that was sold several years ago. Bob said that in 1999-2000, Kingsford was unable to keep up with product demand as the popularity of barbecuing soared. They turned to a Chinese supplier that they thought could manufacture a product to their high standards. After a few months it became clear that the supplier could not do so, and the importing of Chinese Kingsford was stopped. It was better for Kingsford and its reputation to not satisfy demand and sell less product than to meet demand by selling a sub-standard one.

Ramping up production

Kingsford ramps up charcoal production months in advance in order to satisfy product demand during peak barbecuing season. This is not unlike a candy maker that builds up inventory months in advance of Valentine’s Day.

New production plant under construction

Kingsford plans to open another production facility in Mississippi. It takes about three years to open a new plant—two years to complete the planning and regulatory processes and about a year for construction.

More Information About New Kingsford

For more information about new Kingsford, including frequently asked questions, read Kingsford Charcoal Briquets: New Design, New Formula For 2006.

More Kingsford Links On TVWB

- Burn Test 2022: Kingsford Original vs Franklin Barbecue vs B&B Competition Oak Charcoal Briquets

- Burn Test: 1984 Kingsford vs 2020 Kingsford

- Kingsford Long-Burning Charcoal Briquets & Weber 100% All Natural Hardwood Charcoal Briquettes Burn Test 2017

- Kingsford Professional Briquets Replace Competition Briquets

- New Kingsford Original Charcoal Briquets Formula For 2015

- Kingsford Charcoal Briquets – Minor Changes For 2010

- Kingsford Competition Briquets – New For 2009

- Kingsford Charcoal Briquets – New Design, New Formula For 2006

- All About Charcoal